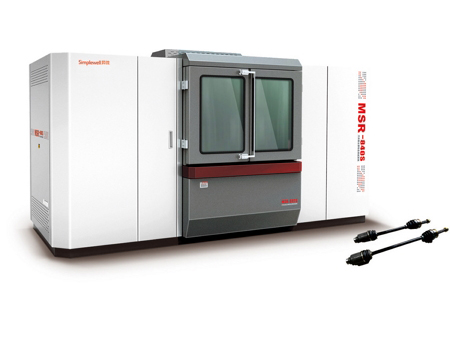

VOC Pretreatment Chamber

- Model: V-MH

- Temperature range: 23℃ (±0.5℃) - 25℃ (±0.5℃)

- Humidity range: 45% (±2.5%) - 50% (±2.5%)

- Internal volume: 24m3 or customized

As the pretreatment chamber provides standard temperature, humidity and clean environment and ensures balance between temperature, humidity, pressure and VOC emission, it’s extremely suitable for testing pollutant emission rate and emission characteristics of materials and products. A wide application is found in testing nonmetal car components, like car floor, carpet, internal decoration and dash board, etc.

Technical Parameters of VOC Pretreatment Chamber

When the concentration of VOC is less than 6.0PPM, the VOC pretreatment chamber ensures a removal rate of more than 90%. And the final TVOC concentration can be lowered to 0.35 mg/ m3 (350μg/ m3) and the concentration of other volatile organic compounds is as follows:

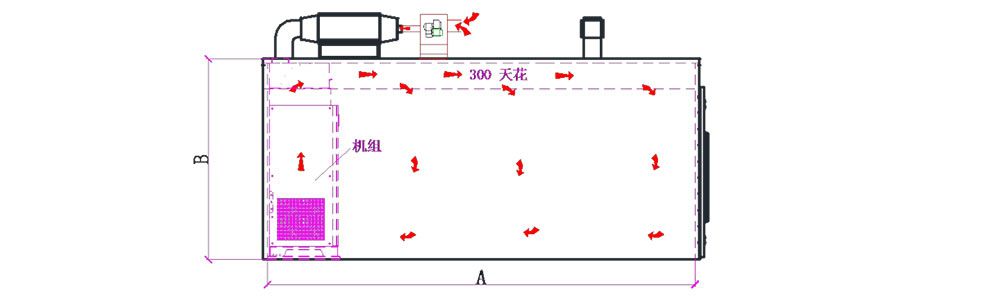

Schematic diagram

The VOC pretreatment system is mainly composed of machine unit, filter, sealing door, observation window, etc.

Working PrinciplesPlace the sample of material or product in the pretreatment chamber and adjust the temperature, relative humidity, air speed, pressure and other environmental parameters. By doing so, the VOC emission volume and emission speed can be stabilized, at the same time, the cross contamination of samples is avoided.

| Background concentration | Outlet air: TVOC≤350ug/m3 | |||

| Benzene | ≤15ug/m3 | Acetaldehyde | ≤15ug/m3 | |

| Methylbenzene | ≤15ug/m3 | Ethylbenzene | ≤15ug/m3 | |

| Xylene | ≤15ug/m3 | Formaldehyde | ≤15ug/m3 | |

| Acetone | ≤15ug/m3 | Styrene | ≤2ug/m3 | |

- The pretreatment chamber is known for its flame retardant capacity, thanks to the stainless steel cover and PU interlayer.

- The sealing door has a size of (1m + 1m)×1.8 m, with high toughness and good air tightness. An observation window (H500 × W340 mm) is also installed on the door, with nitrogen filled in the hollow layer. The internal surface of the window is coated with EC film for anti-condensation performance.

- 1. Control System

The control system mainly consists of a pair of ROTRONIC temperature and humidity sensor, observation window, Mitsubishi PLC controller and LCD dot-matrix touchscreen. Outstanding advantages of this modern control system are, two language options (Chinese and English), high data accuracy (temperature: 0.01℃, humidity: 0.1%RH, time: min), operation curve graph, temperature and humidity adjustment and malfunction alarm and diagnosis. -

2. Cooling System

For the cooling system, air cooling system and water cooling system are accessible. The functional cooling system includes these following parts, compressor (European famous brand), refrigerant (Environmental protection type), magnetic valve, expansion valve, dry filter and oil separator. -

3. Air Duct

In the pretreatment chamber, efficient air circulation is achieved by centrifugal fans, leading to uniform temperature and humidity. Fresh air is blown into the chamber at the upper side and recovered at the lower side. -

4. Heating and Humidifying System

As for air heating, we implements explosion-proof type stainless steel fin tubes which are equipped with empty-run protection device. The controller provides P.I.D. (Proportion, integral, derivative) control, with easy operation and flexible use. When it comes to humidity adjustment, electric-heating steam humidifier and condensation method is applied for dehumidification.